How To Adjust A Hydraulic Pump Output Pressure

Auto Amazon Links: No products found.

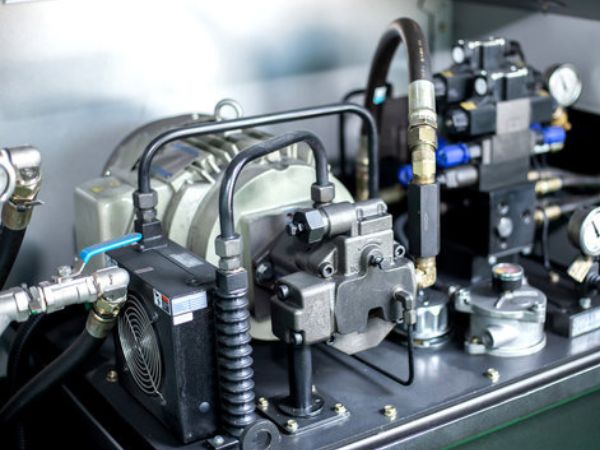

Hydraulic systems play a crucial role in various industries, powering machinery and equipment with the force of pressurized fluids. One critical aspect of hydraulic systems is the output pressure generated by the hydraulic pump. The output pressure directly impacts the performance and efficiency of the entire system. Therefore, it is essential to understand how to adjust a hydraulic pump output pressure to optimize system operation.

Contents

- 1 The Importance of Proper Hydraulic Pump Output Pressure

- 2 Safety Precautions for Adjusting Hydraulic Pump Output Pressure

- 3 Tools and Equipment Needed for Adjusting Hydraulic Pump Output Pressure

- 4 Step-by-Step Guide: How To Adjust A Hydraulic Pump Output Pressure

- 4.1 Identifying the Need for Adjusting Hydraulic Pump Output Pressure

- 4.2 Common Symptoms of Incorrect Hydraulic Pump Output Pressure

- 4.3 Understanding the Pressure Adjustment Mechanism in Hydraulic Pumps

- 4.4 Determining the Desired Output Pressure for Your Hydraulic System

- 4.5 How to Measure Hydraulic Pump Output Pressure

- 4.6 Factors Affecting Hydraulic Pump Output Pressure

- 4.7 Adjusting Hydraulic Pump Output Pressure for Optimal Performance

- 4.8 Fine-Tuning the Output Pressure: Tips and Techniques

- 4.9 Troubleshooting Common Issues When Adjusting Hydraulic Pump Output Pressure

- 4.10 Adjusting Hydraulic Pump Output Pressure for Different Applications

- 4.11 Best Practices for Maintaining Proper Hydraulic Pump Output Pressure

- 4.12 Consulting a Professional: When to Seek Expert Advice for Adjusting Hydraulic Pump Output Pressure

- 5 Conclusion: Mastering the Art of Adjusting Hydraulic Pump Output Pressure

- 6 FAQs

The Importance of Proper Hydraulic Pump Output Pressure

Maintaining the correct hydraulic pump output pressure is vital for the overall functionality and longevity of hydraulic systems. If the output pressure is too low, the system may fail to generate sufficient force to operate machinery effectively. On the other hand, excessive pressure can lead to premature wear and tear, leaks, or even catastrophic system failure. Adjusting the hydraulic pump output pressure ensures that the system operates within safe limits while delivering optimal performance.

Safety Precautions for Adjusting Hydraulic Pump Output Pressure

Before embarking on adjusting hydraulic pump output pressure, it is crucial to prioritize safety. Hydraulic systems operate under high pressure, which can pose significant risks if not handled with care. To ensure safety, follow these precautions:

- Familiarize yourself with the hydraulic system and the specific pump you are working on by consulting the equipment manual or seeking expert advice.

- Wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and protective clothing to safeguard against potential hazards.

- Shut down the system and relieve all pressure before attempting any adjustments. Follow proper lockout/tagout procedures to ensure no accidental start-ups occur.

- Use caution while working with hydraulic components and avoid placing your hands or body near moving parts or potential pinch points.

- Work in a well-ventilated area and beware of hydraulic fluid leaks, as they can be hazardous to health and cause slip hazards.

Tools and Equipment Needed for Adjusting Hydraulic Pump Output Pressure

To adjust hydraulic pump output pressure, you will need the following tools and equipment:

- Pressure gauge: A reliable pressure gauge capable of measuring the desired range of hydraulic pressures accurately.

- Wrenches: To loosen and tighten hydraulic fittings, depending on the pump design.

- Allen keys or screwdrivers: These tools may be necessary to access pressure adjustment screws or valves on certain pump models.

- Teflon tape or thread sealant: Used to ensure leak-free connections when reassembling fittings.

- Hydraulic fluid: Adequate hydraulic fluid may be required to replenish the system if adjustments involve draining and refilling.

Step-by-Step Guide: How To Adjust A Hydraulic Pump Output Pressure

Follow these steps to adjust the hydraulic pump output pressure effectively:

Identifying the Need for Adjusting Hydraulic Pump Output Pressure

The first step is to identify whether there is a need to adjust the hydraulic pump output pressure. Some signs that indicate the need for adjustment include:

- Insufficient force or speed in hydraulic actuators or cylinders.

- System components not reaching the desired operating temperature.

- Leaks or unusual noises coming from the system.

- Excessive wear on system components.

Common Symptoms of Incorrect Hydraulic Pump Output Pressure

If the hydraulic pump output pressure is not properly adjusted, you may encounter the following symptoms:

- Slow or sluggish system response.

- Inconsistent or uneven operation of hydraulic cylinders or actuators.

- Overheating of hydraulic fluid or system components.

- Leaks at fittings or seals.

- Excessive noise or vibration during system operation.

Understanding the Pressure Adjustment Mechanism in Hydraulic Pumps

Different types of hydraulic pumps have varying methods for adjusting output pressure. Some pumps feature an adjustable relief valve, while others utilize an internal pressure compensator or variable displacement mechanism. Consult the pump manufacturer’s manual or seek expert advice to determine the specific pressure adjustment mechanism in your hydraulic pump.

Determining the Desired Output Pressure for Your Hydraulic System

Before adjusting the hydraulic pump output pressure, it is essential to determine the desired pressure for your specific hydraulic system. This will depend on factors such as the machinery’s requirements, load capacity, and the type of hydraulic actuators or cylinders being used. Consulting the equipment manual or seeking expert guidance will help you identify the optimal output pressure range for your system.

How to Measure Hydraulic Pump Output Pressure

To accurately measure the hydraulic pump output pressure, follow these steps:

- Identify a suitable pressure port on the hydraulic system where you can connect the pressure gauge. Consult the equipment manual for the recommended port.

- Shut down the hydraulic system and relieve all pressure.

- Attach the pressure gauge to the designated port using appropriate fittings or adapters.

- Slowly start the system and monitor the pressure gauge reading. Allow the system to stabilize before noting the pressure.

- Record the pressure reading as the current output pressure.

Factors Affecting Hydraulic Pump Output Pressure

Several factors can impact the hydraulic pump output pressure, including:

- Pump settings: Some hydraulic pumps have adjustable settings or mechanisms that directly control the output pressure. These settings may include relief valves, compensators, or variable displacement mechanisms.

- System load: The load placed on the hydraulic system, such as the weight being lifted or the resistance encountered by actuators, can affect the output pressure.

- Fluid viscosity: The viscosity of the hydraulic fluid can influence the pump’s ability to generate pressure. Higher viscosity fluids may require adjustments to maintain optimal output pressure.

- Temperature variations: Changes in ambient or operating temperatures can affect the hydraulic fluid’s properties and, consequently, the pump’s output pressure.

Adjusting Hydraulic Pump Output Pressure for Optimal Performance

To adjust the hydraulic pump output pressure, follow these general steps:

- Locate the pressure adjustment mechanism on your hydraulic pump. This may be a relief valve, compensator, or variable displacement mechanism.

- Before making any adjustments, consult the equipment manual or seek expert advice to ensure you understand the specific adjustment procedure for your pump.

- Slowly and incrementally adjust the pressure setting, either by turning a pressure adjustment screw, changing the compensator setting, or utilizing the appropriate method for your pump.

- Monitor the pressure gauge as you make adjustments and observe the impact on the system’s performance.

- Aim to achieve the desired output pressure within the recommended range for your system. Take note of any changes in system response, speed, or noise levels.

Fine-Tuning the Output Pressure: Tips and Techniques

When fine-tuning the hydraulic pump output pressure, consider the following tips and techniques:

- Make small adjustments: Avoid making large pressure adjustments at once. Instead, make small incremental changes and observe the system’s response before making further adjustments.

- Monitor system performance: Pay close attention to how the system behaves after each adjustment. Note any changes in speed, force, or stability, and adjust accordingly to optimize performance.

- Seek expert advice if necessary: If you encounter challenges or uncertainties while adjusting the output pressure, it is advisable to consult a hydraulic system professional for guidance. They can provide valuable insights and ensure accurate adjustments.

Troubleshooting Common Issues When Adjusting Hydraulic Pump Output Pressure

During the adjustment process, you may encounter some common issues. Here are troubleshooting tips for addressing them:

- System instability: If adjusting the output pressure leads to unstable system behavior, it may indicate an underlying problem with other system components. Inspect and troubleshoot the valves, actuators, and other parts of the hydraulic system to identify and address the root cause.

- Pressure spikes or fluctuations: Rapid pressure changes or fluctuations can be indicative of a faulty relief valve or compensator mechanism. Inspect these components for any signs of damage or improper settings. Adjust or replace them as necessary to ensure stable pressure output.

- Inconsistent pressure adjustment: If you find it challenging to achieve a consistent and accurate pressure adjustment, consider checking for any clogs or restrictions in the hydraulic lines or filters. Clean or replace these components to ensure proper fluid flow and pressure regulation.

- Excessive noise or vibration: Unusual noise or vibration during the adjustment process may indicate a problem with the hydraulic pump or other system components. Inspect for loose fittings, worn-out parts, or damaged components, and address them accordingly.

Adjusting Hydraulic Pump Output Pressure for Different Applications

Different applications may require specific adjustments to the hydraulic pump output pressure. For example:

- Heavy machinery: Applications involving heavy machinery or equipment may require higher output pressures to generate sufficient force for lifting or moving heavy loads. Adjust the pump output pressure accordingly to meet the specific load requirements.

- Precision applications: Some applications, such as precision machining or delicate operations, may require lower output pressures to ensure precise control and prevent damage to sensitive components. Adjust the pump output pressure within the desired range for these applications.

- Temperature-sensitive applications: Certain applications may be sensitive to temperature variations. In such cases, adjust the hydraulic pump output pressure to compensate for temperature changes and maintain consistent performance.

Best Practices for Maintaining Proper Hydraulic Pump Output Pressure

To ensure the ongoing efficiency and performance of your hydraulic system, follow these best practices:

- Regular inspections: Conduct routine inspections of the hydraulic system, including the pump, valves, fittings, and pressure gauges, to identify any potential issues or leaks. Address them promptly to prevent further damage and maintain proper pressure regulation.

- Fluid maintenance: Maintain the appropriate hydraulic fluid level and quality. Regularly check for contamination, and change or filter the fluid as needed to prevent damage to the pump and other system components.

- Calibration and adjustments: Periodically recalibrate and readjust the hydraulic pump output pressure to account for any changes in system requirements or wear on components.

- Training and documentation: Ensure that personnel working with hydraulic systems receive proper training on adjusting pump output pressure and following safety protocols. Keep detailed documentation of adjustments made, maintenance performed, and any issues encountered for future reference.

Consulting a Professional: When to Seek Expert Advice for Adjusting Hydraulic Pump Output Pressure

While it is possible to adjust hydraulic pump output pressure independently, there are instances when consulting a professional becomes necessary. Consider seeking expert advice in the following situations:

- Lack of experience: If you are unfamiliar with hydraulic systems or lack experience in adjusting pump output pressure, it is wise to consult a hydraulic specialist or technician who can provide guidance and ensure accurate adjustments.

- Complex systems: Some hydraulic systems may have intricate designs or unique pressure adjustment mechanisms that require specialized knowledge. In such cases, consulting an expert can prevent potential errors or damage.

- Persistent issues: If you encounter persistent issues or difficulties in adjusting the pump output pressure, despite following the proper procedures, it is advisable to seek professional assistance. An expert can diagnose and resolve underlying problems that may be affecting pressure regulation.

Conclusion: Mastering the Art of Adjusting Hydraulic Pump Output Pressure

Adjusting hydraulic pump output pressure is a crucial skill for maintaining the performance and efficiency of hydraulic systems. By understanding the importance of proper pressure regulation, following safety precautions, and using the right tools, you can effectively adjust the output pressure to meet specific system requirements. Remember to monitor system performance, troubleshoot any issues, and seek expert advice when needed. With proper adjustment and maintenance, you can optimize the functionality and lifespan of your hydraulic system.

FAQs

Q: Can I adjust the hydraulic pump output pressure without shutting down the system?

A: No, it is essential to shut down the hydraulic system and relieve all pressure before attempting any adjustments. Failure to do so can lead to serious safety hazards and damage to the system components.

Q: How often should I check and adjust the hydraulic pump output pressure?

A: The frequency of checking and adjusting the hydraulic pump output pressure depends on the specific requirements of your hydraulic system. However, it is generally recommended to include it as part of regular maintenance routines, such as during scheduled inspections or when you notice any performance issues.

Q: What is the ideal output pressure range for a hydraulic system?

A: The ideal output pressure range varies depending on the specific hydraulic system and its application. Consult the equipment manual or seek expert advice to determine the optimal pressure range for your system.

Auto Amazon Links: No products found.

Auto Amazon Links: No products found.