What Size Inverter To Run Circular Saw

Auto Amazon Links: No products found.

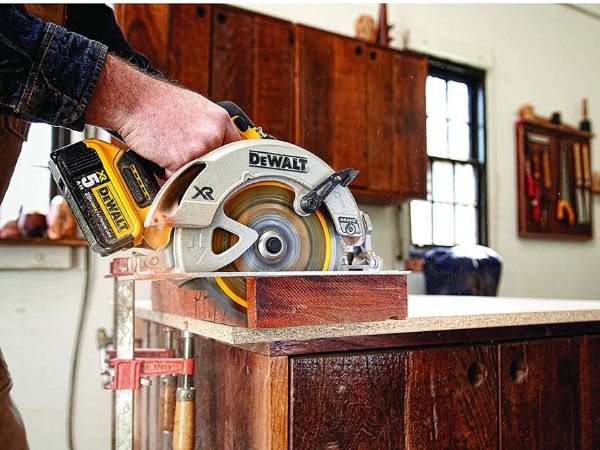

Circular saws are powerful tools that can help you complete a wide range of woodworking projects. However, they require a lot of power to operate, and not all locations have access to a power outlet. That’s where an inverter comes in handy. An inverter can convert DC power from a battery into AC power that can be used to power your circular saw. In this article, we will discuss what size inverter to run circular saw, the benefits of using an inverter with a circular saw, and how to connect an inverter to a circular saw.

Contents

- 1 What is an inverter?

- 2 Understanding power requirements for circular saws

- 3 Why use an inverter with a circular saw?

- 4 How to determine the size of inverter needed for a circular saw

- 5 What factors affect the size of inverter needed for a circular saw?

- 6 Choosing the right type of inverter for a circular saw

- 7 Inverter safety precautions for using a circular saw

- 8 Here are some general safety precautions to keep in mind:

- 9 Common mistakes to avoid when using an inverter with a circular saw

- 10 Can a small inverter run a circular saw?

- 11 What are the risks of using an undersized inverter with a circular saw?

- 12 What are the benefits of using the correct size inverter with a circular saw?

- 13 How to properly connect an inverter to a circular saw

- 14 Best practices for using an inverter with a circular saw

- 15 Can multiple tools be used with an inverter?

- 16 Understanding the difference between continuous and surge power ratings

- 17 How to calculate surge power requirements for a circular saw

- 18 What to consider when choosing a battery for an inverter

- 19 Inverter options for circular saws in different settings

- 20 Conclusion and final thoughts on using an inverter with a circular saw

- 21 FAQs

What is an inverter?

An inverter is a device that converts DC (direct current) power into AC (alternating current) power. DC power is typically generated by batteries or solar panels, while AC power is the type of power that is found in most homes and businesses. Inverters come in a variety of sizes and capacities, and are used for a wide range of applications, from powering small electronics to running large appliances.

Understanding power requirements for circular saws

Circular saws are power-hungry tools that require a lot of power to operate. The power requirements for a circular saw depend on several factors, including the motor size, the blade size, and the type of material being cut. A typical circular saw may require anywhere from 1200 to 2400 watts of power to operate.

Why use an inverter with a circular saw?

There are several reasons why you might want to use an inverter with a circular saw. One reason is that it allows you to use your saw in remote locations where there is no access to a power outlet. It also allows you to use your saw without the need for an extension cord, which can be a safety hazard. Additionally, an inverter can provide a stable source of power, which can help to extend the life of your saw.

How to determine the size of inverter needed for a circular saw

To determine the size of inverter needed for your circular saw, you will need to know the wattage requirements of your saw. This information can usually be found in the owner’s manual or on the tool itself. Once you know the wattage requirements, you will need to choose an inverter that can provide enough power to meet those requirements. It’s important to choose an inverter that has a continuous power rating that is equal to or greater than the wattage requirements of your saw.

What factors affect the size of inverter needed for a circular saw?

There are several factors that can affect the size of inverter needed for a circular saw. One of the most important factors is the motor size of the saw. Larger motors require more power to operate, so if you have a circular saw with a large motor, you will need a larger inverter to power it. Other factors that can affect the size of inverter needed include the blade size, the type of material being cut, and the length of time the saw will be used.

Choosing the right type of inverter for a circular saw

There are two main types of inverters: modified sine wave inverters and pure sine wave inverters. Modified sine wave inverters are less expensive, but they may not be suitable for some types of equipment, including circular saws. Pure sine wave inverters, on the other hand, provide a clean, stable source of power that is suitable for all types of equipment. When choosing an inverter for your circular saw, it’s important to choose a pure sine wave inverter to ensure the safety and proper operation of your saw.

Inverter safety precautions for using a circular saw

When using an inverter with a circular saw, there are several safety precautions that should be followed. First and foremost, it’s crucial to read and understand the manufacturer’s instructions for both the inverter and the circular saw. Familiarize yourself with the safety guidelines and recommendations provided by the manufacturers.

Here are some general safety precautions to keep in mind:

Ensure proper grounding: It’s important to properly ground both the inverter and the circular saw to prevent electrical shocks. Follow the instructions provided with the equipment to ensure a secure and safe grounding connection.

Inspect the equipment: Before using the inverter and circular saw, inspect them for any signs of damage or wear. Check the power cords, plugs, and connections to ensure they are in good condition. Do not use damaged equipment as it may pose a safety risk.

Use appropriate power sources: When using an inverter, make sure you have a reliable and compatible power source, such as a high-quality deep-cycle battery. The battery should have sufficient capacity to meet the power requirements of the circular saw and provide a stable power supply.

Use the correct cables and connectors: Ensure that you use cables and connectors that are designed to handle the power requirements of your circular saw. Inadequate or improperly sized cables can result in power loss, overheating, or damage to the equipment.

Follow proper connection procedures: When connecting the inverter to the circular saw, follow the recommended procedures provided by the manufacturer. Pay attention to the polarity of the connections and ensure a secure and tight fit.

Position the equipment safely: Place the inverter and the circular saw on stable and non-flammable surfaces. Keep them away from water, excessive heat, and flammable materials to minimize the risk of accidents or damage.

Use personal protective equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection when operating a circular saw. The use of PPE can help prevent injuries and ensure your safety.

Common mistakes to avoid when using an inverter with a circular saw

While using an inverter with a circular saw can be convenient, there are some common mistakes that should be avoided:

Using an undersized inverter: Using an inverter that is not powerful enough to meet the wattage requirements of your circular saw can lead to performance issues, potential damage to the equipment, or even pose a safety risk. Always ensure that the inverter’s continuous power rating is equal to or greater than the wattage requirements of your circular saw.

Neglecting battery capacity: The battery capacity plays a crucial role in determining the runtime of the circular saw. Using a battery with insufficient capacity can result in frequent power interruptions and reduced efficiency. Consider the power requirements of your circular saw and choose a battery with adequate capacity to support the desired runtime.

Improper wiring or connections: Incorrect wiring or loose connections can lead to power fluctuations, overheating, or equipment failure. Always double-check the wiring and connections to ensure they are properly secured and well-maintained.

Overloading the inverter: It’s important to avoid overloading the inverter by connecting additional tools or appliances that exceed its power capacity. Overloading can cause the inverter to trip or malfunction, potentially damaging the equipment.

Can a small inverter run a circular saw?

Using a small inverter to power a circular saw is generally not recommended. Circular saws require a significant amount of power to operate, and smaller inverters may not be able to provide the necessary wattage. Attempting to run a circular saw on a small inverter could result in the inverter being overloaded, which can lead to reduced performance, equipment damage, or even pose a risk of electrical hazards or fire. It’s important to choose an inverter that can handle the power requirements of your circular saw to ensure safe and efficient operation.

What are the risks of using an undersized inverter with a circular saw?

Using an undersized inverter with a circular saw can pose several risks. Firstly, the inverter may not be able to deliver the required power to the saw, resulting in reduced performance or the inability to operate the tool at all. This can lead to frustration and delays in your work.

Additionally, an undersized inverter may struggle to handle the load, causing it to overheat or trip its internal safety features. This can result in frequent power interruptions and potentially damage the inverter or other connected equipment.

Furthermore, using an undersized inverter puts excessive strain on the battery, which can shorten its lifespan or cause it to degrade more quickly. It may also result in the battery discharging at a faster rate, reducing the overall runtime of your circular saw.

In worst-case scenarios, using an undersized inverter could lead to electrical hazards such as electrical shocks or fires. The inadequate power supply may cause the equipment to malfunction or overheat, creating unsafe conditions in your workspace.

What are the benefits of using the correct size inverter with a circular saw?

Using the correct size inverter for your circular saw offers several benefits. Firstly, it ensures that the saw receives a consistent and reliable power supply, allowing it to perform optimally. This translates to smoother operation, better cutting performance, and reduced strain on the equipment.

By using the appropriate inverter, you can also extend the lifespan of both the inverter and the circular saw. The correct size ensures that the inverter operates within its designed capacity, reducing the risk of overheating, tripping, or other malfunctions that can damage the equipment.

Moreover, using the correct size inverter promotes safety in the workspace. It minimizes the risk of electrical hazards, such as shocks or fires, as the inverter is operating within its intended parameters. This provides peace of mind and a safer environment for you and those around you.

How to properly connect an inverter to a circular saw

Connecting an inverter to a circular saw requires attention to detail and following the manufacturer’s instructions. Here are the general steps to properly connect an inverter to a circular saw:

Read the manuals: Start by carefully reading the user manuals for both the inverter and the circular saw. Familiarize yourself with the specific instructions, safety guidelines, and any precautions provided by the manufacturers.

Choose the right cables: Ensure you have the appropriate cables and connectors for the connection. The cables should be compatible with the inverter’s output and the circular saw’s power input.

Power off: Make sure both the inverter and the circular saw are turned off and unplugged from any power source before starting the connection process.

Connect the cables: Connect the positive (+) and negative (-) cables from the inverter to the corresponding terminals on the circular saw. Follow the manufacturer’s instructions for the proper connection sequence.

Secure the connections: Ensure that the connections are tight and secure, preventing any accidental disconnections during use. Loose connections can lead to power loss or equipment damage.

Turn on the inverter: Once the connections are secure, turn on the inverter according to the manufacturer’s instructions. The inverter should now be supplying power to the circular saw.

Test the operation: Before using the circular saw, perform a quick test to ensure that it is receiving power from the inverter and operating correctly. Check for any unusual sounds or behavior.

Best practices for using an inverter with a circular saw

To ensure the best performance and safety when using an inverter with a circular saw, follow these best practices:

Choose a high-quality inverter: Invest in a reliable, well-built inverter from a reputable manufacturer. Quality inverters are more likely to provide stable power output and have built-in safety features.

Size the inverter correctly: Determine the power requirements of your circular saw and select an inverter with a continuous power rating equal to or greater than those requirements. Oversizing the inverter slightly can provide a buffer and prevent overloading.

Use a suitable battery: Select a deep-cycle battery with sufficient capacity to support the power demands of your circular saw. Consider factors such as the runtime you need and the battery’s ability to handle the load.

Maintain the battery: Regularly inspect and maintain your battery to ensure it remains in good condition. Follow the manufacturer’s recommendations for charging, storage, and maintenance to maximize its lifespan.

Monitor power consumption: Keep an eye on the power consumption of your circular saw and other tools connected to the inverter. If you notice any fluctuations or issues, investigate and address them promptly to avoid potential problems.

Follow safety guidelines: Always prioritize safety when operating the circular saw and using the inverter. Wear appropriate personal protective equipment (PPE), adhere to the manufacturer’s safety recommendations, and follow general power tool safety practices.

Properly store and transport equipment: When not in use, store the inverter and circular saw in a clean, dry, and secure location. Ensure they are properly protected during transportation to prevent damage.

Can multiple tools be used with an inverter?

Yes, an inverter can power multiple tools simultaneously, but it is crucial to consider the power requirements of each tool and ensure that the inverter’s capacity is sufficient to handle the combined load. Calculate the total power consumption of all the tools you intend to use and select an inverter with a continuous power rating that exceeds the total wattage.

Understanding the difference between continuous and surge power ratings

Inverters have two power ratings: continuous power rating and surge power rating. The continuous power rating indicates the amount of power the inverter can supply over an extended period. Surge power rating, on the other hand, represents the inverter’s ability to handle brief power surges that occur when starting motor-driven tools.

When choosing an inverter for a circular saw, focus on the continuous power rating. Ensure it matches or exceeds the saw’s power requirements to ensure consistent operation. While the surge power rating is important, it is primarily relevant for tools with high starting current, such as compressors or motors.

How to calculate surge power requirements for a circular saw

To calculate the surge power requirements for a circular saw, you need to determine the starting current or surge current of the saw. This information is usually provided by the manufacturer and can be found in the saw’s specifications or user manual.

Once you have the surge current value, multiply it by the voltage (typically 120V in the United States) to obtain the surge power requirement in watts. It’s essential to choose an inverter with a surge power rating that can handle this calculated surge power requirement to ensure smooth startup and operation of the circular saw.

What to consider when choosing a battery for an inverter

When choosing a battery for an inverter, consider the following factors:

Capacity: Select a battery with sufficient capacity to meet your circular saw’s runtime requirements. The battery’s capacity is usually measured in ampere-hours (Ah) or watt-hours (Wh).

Battery type: The most common types of batteries used with inverters are lead-acid batteries (such as AGM or deep-cycle batteries) and lithium-ion batteries. Each type has its pros and cons, so choose one based on your specific needs, budget, and considerations like weight, maintenance requirements, and lifespan.

Voltage: Ensure that the battery’s voltage matches the input voltage requirement of your inverter. Most inverters are designed for 12V, 24V, or 48V battery systems.

Cycle life: Consider the cycle life of the battery, which refers to the number of charge-discharge cycles it can endure before its capacity significantly diminishes. Opt for a battery with a higher cycle life if you anticipate frequent use of the circular saw.

Charging options: Determine whether the battery can be easily recharged using your available resources. Some batteries can be charged using solar panels, generators, or grid power, providing flexibility in different settings.

Portability: If portability is important to you, consider the weight and size of the battery. Some batteries are more compact and lightweight, making them easier to transport.

Safety features: Look for batteries with built-in safety features such as overcharge protection, short-circuit protection, and thermal management systems. These features enhance the safety and longevity of the battery.

Manufacturer’s reputation: Choose a battery from a reputable manufacturer known for producing reliable and high-quality products. Read reviews and consider warranties offered by the manufacturer.

Inverter options for circular saws in different settings

The choice of inverter for a circular saw may vary depending on the setting in which it will be used. Here are some options to consider:

Off-grid or remote locations: If you’re working in off-grid or remote locations where grid power is unavailable, a standalone inverter system with a battery bank and renewable energy sources like solar panels or wind turbines can provide a reliable power solution.

Job sites or construction sites: For portable use in job sites or construction sites, consider a portable inverter generator. These units combine an inverter with a gasoline or diesel-powered generator, providing a versatile and independent power source.

Indoor workshops or professional use: In a workshop or professional setting where access to grid power is available, a grid-tied inverter can be used. These inverters are designed to be connected to the electrical grid and can supplement power from the grid while feeding excess power back to it.

Mobile setups or vehicles: If you require power for your circular saw in a mobile setup or vehicle, you can opt for a power inverter specifically designed for automotive applications. These inverters connect directly to the vehicle’s battery and provide AC power for your tools.

Conclusion and final thoughts on using an inverter with a circular saw

Using an inverter with a circular saw can provide flexibility and convenience, allowing you to power your tool in various settings. However, it is crucial to select the right size inverter, consider power requirements, and prioritize safety.

By understanding the power needs of your circular saw, sizing the inverter appropriately, and following proper connection procedures, you can ensure efficient and safe operation. Additionally, adhering to safety precautions, avoiding common mistakes, and choosing high-quality equipment will contribute to a positive experience when using an inverter with a circular saw.

Remember to always prioritize safety, wear appropriate personal protective equipment, and follow the manufacturer’s guidelines for both the inverter and circular saw. By doing so, you can enjoy the benefits of using an inverter while operating your circular saw with confidence and efficiency.

FAQs

Can I use a small inverter to run a circular saw?

Using a small inverter to run a circular saw is generally not recommended. Circular saws require a significant amount of power, and a small inverter may not be able to deliver the necessary wattage. It is best to select an inverter with a continuous power rating that meets or exceeds the saw’s power requirements.

Can I use a modified sine wave inverter with a circular saw?

It is generally recommended to use a pure sine wave inverter with sensitive electronic devices and power tools like circular saws. Modified sine wave inverters produce a modified or stepped waveform, which can introduce harmonic distortion and may not be suitable for some devices.

Can I run a cordless circular saw using an inverter?

No, cordless circular saws are designed to be powered by their specific battery packs and do not require an inverter. These saws have built-in battery systems that provide the necessary power for their operation. Using an inverter to power a cordless circular saw would be unnecessary and inefficient.

Auto Amazon Links: No products found.

Auto Amazon Links: No products found.